Mobile

(Summary description)Diaphragm compressor is mainly composed of crankcase parts, crankshaft connecting rod, crosshead, piston, cylinder components, cooler, pipelines, chassis, instrument panel, motor etc.. The structure form of compressor is divided into four types of L,Z,V,D according to the forms of cylinder.

(Summary description)Diaphragm compressor is mainly composed of crankcase parts, crankshaft connecting rod, crosshead, piston, cylinder components, cooler, pipelines, chassis, instrument panel, motor etc.. The structure form of compressor is divided into four types of L,Z,V,D according to the forms of cylinder.

Summary: Diaphragm compressor's structure, working principle and application.

2.Overview of structure,working principle and application

2.1 Overview of structure

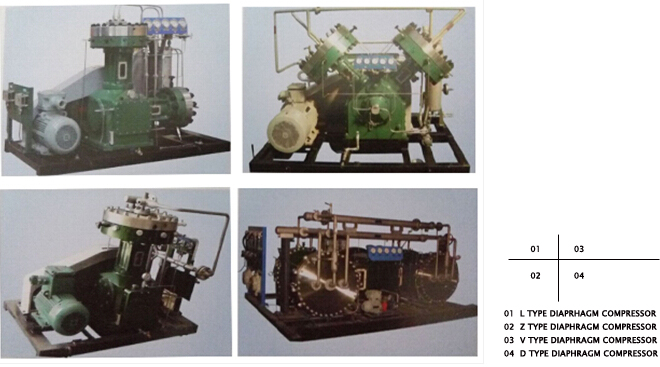

Diaphragm compressor is mainly composed of crankcase parts, crankshaft connecting rod, crosshead, piston, cylinder components, cooler, pipelines, chassis, instrument panel, motor etc.. The structure form of compressor is divided into four types of L,Z,V,D according to the forms of cylinder.

L type: The vertical and horizonal cylinder of L type diaphragm compressor constitute L type, and the shape is similar to letter L.(see the picture)

Z type: Z type diaphragm compressor only includes a vertical cylinder, and the shape is similar to letter Z.(see the picture)

V type: The left and right cylinder of V type diaphragm compressor constitute V type, and the shape is similar to letter V.(see the picture)

D type: D type diaphragm compressor is the symmetrical balanced structure, and its cylinder parts including two, three and four cylinder. (See the picture, it is the four-cylinder-type)

The structure of cylinder is the same with others, including cover, cylinder block, diaphragm and other parts. There is a hook face with special shape respectively locates on the cylinder’s cover and block, a set of metal diaphragm is clamped in the middle to form two cavities, which on the side of cylinder cover is the gas cylinder and on the side of cylinder block is the oil cylinder that is interlinked with the piston through many radiation oil conduit holes on the cylinder block. The cylinder block should be equipped with cylinder liner, and the piston will proceed reciprocating motion within the cylinder liner. There are inlet and exhaust valve holes on the cylinder cover, and the exhaust valve hole is located in the centre of cylinder cover, and the rest are all inlet valve holes, commonly there is only 1 or 2. The inlet and exhaust valve of compressor is respectively placed and compacted by the pressure pipe in the inlet and exhaust valve hole of the cylinder cover.

2.2 Working principle

Diaphragm compressor is a special positive displacement compressor. Electric motor is the driving force to drive diaphragm compressor’s crankshaft by belt or coupling, and the crankshaft’s rotation forces the connecting rod installed on the bellcrank of crankshaft to do planar motion so as to bring along the crosshead and piston installed on the connecting rod small end to do reciprocating linear motion, the range of motion equals to 2 times of bellcrank’s radius of crankshaft, that is 1 route, the motion frequency is rotation times of crankshaft.

Take the position that the piston situates at top dead center as the start point, when the crankshaft rotates, the piston starts to move down, the diaphragm gradually deforms towards the side of cylinder block with the action of the flowing of hydraulic oil and the diaphragm itself elastic force, at this time the gas cylinder volume is gradually increasing, firstly the residual gas in clearance is inflated, then gas is inhaled by gas suction valve of gas cylinder; when the piston rotates at lower dead center, the diaphragm arrives at the lower extreme position, and the suction process in gas cylinder is finished.

Then, the piston starts to move up to prompt hydraulic oil flowing and evenly applies force on the diaphragm through many holes and ring grooves of cylinder block to boost upward deformation of the diaphragm, at this time, gas begins to be compressed in the cylinder block. When this pressure is higher than the pressure of gas in discharge gas pipe, the discharge valve will open automatically, and the gas is pressed out; the piston continues to move upward to force the diaphragm cling tightly to the hook face of cylinder cover to cleanly evacuate the gas, then the discharge process is finished.

The hydraulic oil of the piston in the reciprocating motion prompts the diaphragm vibrating back and forth. With the cooperation of suction and discharge valve, one cyclic process of inflation, suction, compression and discharge in the cylinder block is finished every vibration cycle of the diaprhagm, thus the pressure for transmitting gas is raised.

A part of hydraulic oil in oil cylinder will leak into the crankcase through clearance between piston rings and cylinder liner walls, ring grooves. In order to make the diaprhagm cling tightly to the hook face of cylinder cover and cleanly evacuate the compression media, the compressor is equipped with compensating oil pump. This pump will inject oil into oil cylinder in the suction process, the injection oil volume is slightly more than the leaking oil volume, the excess oil will reflow to crankcase by regulating valve or slave valve that controls oil pressure under the set pressure.

Due to the gas cylinder and oil cylinder is completely separated by diaphragm, the diaphragm itself does reciprocating motion and plays the role of piston, there is no need to add any lubricating material to gas cylinder. Compression media only contac with metal diaphragm without any contamination, which ensures the purity. The cylinder is composed of hook face of cylinder cover and diaphragm, it is a closed empty cavity with excellent sealing property, thus diaphragm compressor can be used to compress high purity gases that commonly can attain the purity of 99.999%.

Diaphragm compressor is especially suitable for compression, transmitting, cylinder filling of valued and rare gas, furthermore, it is also suitable for strongly corrosive, toxic, flammable, explosive and radioactive gases. Diaphragm compressor’s cylinder block has good heat dissipation performance, so it can take use of high compression ratio thus providing wide pressure range from extremely low pressure up to 200Mpa. It can be applied in fields of industrial gas, food industry, petrochemical industry, nucler power, earospace and aviation, military equipment and scientific research etc.

2.3 Application

Diaphragm compressor can be applied to compress air, hydrogen, nitrogen, oxygen, inert gases, carbon dioxide, carbon monoxide, methane gas, natural gas, ethylene, tetrafluoroethylene, hexafluoropropylene and ammonia etc., but different gases has different configurations and requirements which can be applied based on technical agreements.

Scan the QR code to read on your phone

Mobile

Sichuan New Tianyuan Technology Co., Ltd. All rights reserved | www.300.cn | 蜀ICP备2021012412号-1